GRP(Glass Reinforced Plastic) is widely used throughout industry, being cost effective, highly durable and due to its flexible process, has variety of different uses.

GRP is an excellent lining system is compared to coatings such as expoxies and urethanes, due to the way the system is applied and thickness to which it is applied. It is applied in sheets rather the wallpapering and the advantage GRP has over coatings is that it will cover cracks and even large holes. Expoxies are painted on at thickness of around 0.5mm. It is possible to cover defects and uneven substrates with a minimum of 3mm thickness, giving a very strong but still flexible costing.

APPLICATION METHOD GRP

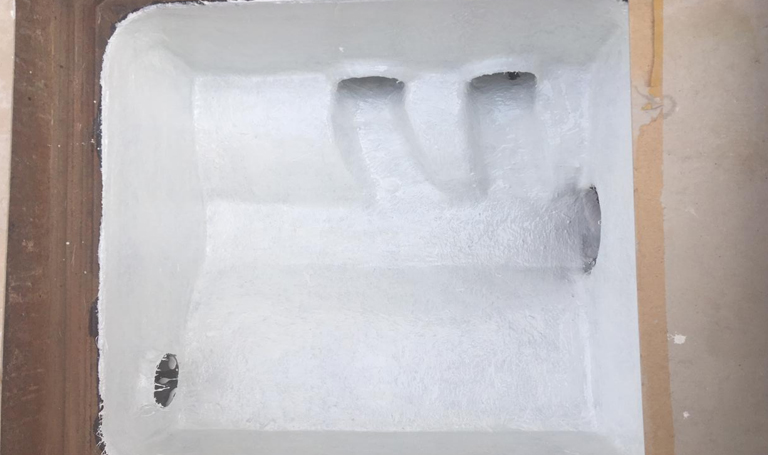

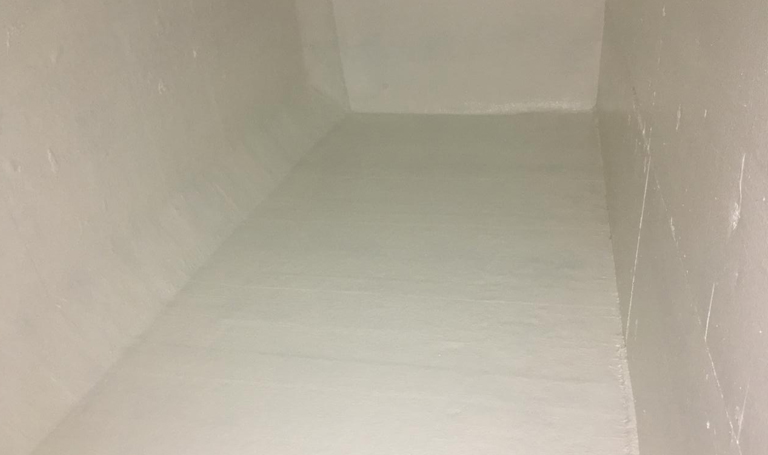

The surface is normally prepared by grit blasting to the standard required for the application. This ensures good bonding of the lining system to the surface.

All prepared areas are then primed with a coat of resin.

CSM(Chopped Strand Mat) is applied to all primed areas. Layers of CSM are applied to construct the thickness required.

A chemical required tissue is a combination of resins. is applied to improve the chemical resistance and also to prevent pinholes.

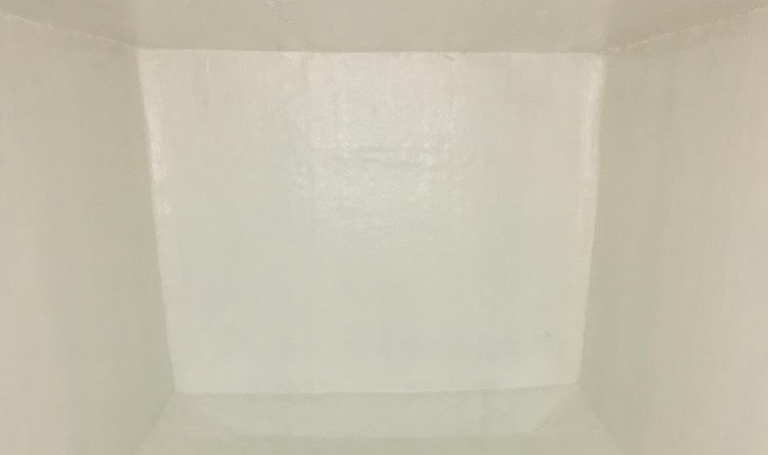

A resin wash, which is combination of resins, is applied to all areas. The resin wash is pigmented to the required color, and once cured leaves a smooth gloss finish.

The resin washed lining system is then sanded to remove any irregularities. All debris and dust is removed from the area.

A GEL Coat applied to finish the lining system.

Call us get it done

When you hire us for construction services, you know you're getting highly qualified professionals who have the expertise and experience to make sure your project is done properly and functions.

Call us on

0529699624

Email us

Info@gsw-tech.com

.jpg)